How Ball Bearings Changed The World

Everyone knows that the invention of the wheel changed the course of history forever, but very few people realize that the ball bearing not only significantly optimized the function of the wheel, but its responsible for facilitating amazing technological advancements from bicycles and automobiles to wind turbines and jet engines.

There’s lots of evidence that bearings and rollers were utilized before there was a large industrial demand and before the invention of machinery that enabled them to be manufactured in large quantities (read a NASA technical memorandum on the History of Bearings for an extensive background.)

As centuries passed, the manufacturing and usage of the ball bearing has only increased quite substantially, and it has ingeniously been integrated in virtually every mechanical or electrical machine or component that deals with motion and friction.

Some interesting facts about ball bearings

- the average household has at least 100 or more ball bearings in it from the vacuum cleaner to your laptop

- the ball bearing surfaced even before the creation of the wheel

- bearings come in all sizes from extremely tiny (outside diameter of 1.5mm) to over 12 feet in diameter

- bearings are now manufactured as lubricated and non-lubricated

- bearings can be over-lubricated, and thus be more prone to damage and wear

- bearings are generally made of strong stainless steel, bronze, plastic/polymer, but can also be made of ceramic, also known as ceramic bearings

- ceramic balls and races are less susceptible to corrosion

- during world war 2, bearings were mass produced and required in the building of artillery, tanks and other equipment

Supposed inventors of the ball bearing

Some historians, scholars and laymen believe Leonardo Da Vinci invented the ball bearing. Many others claim that the bearing was invented by the Welsh inventor Philip Vaughan who did indeed receive a patent on his ball bearings in 1794.

Although both these men may have refined or mass produced the bearing, the following explains where else in history bearings were used and how far back their usage goes compared to recent history.

Bearings & rollers in history

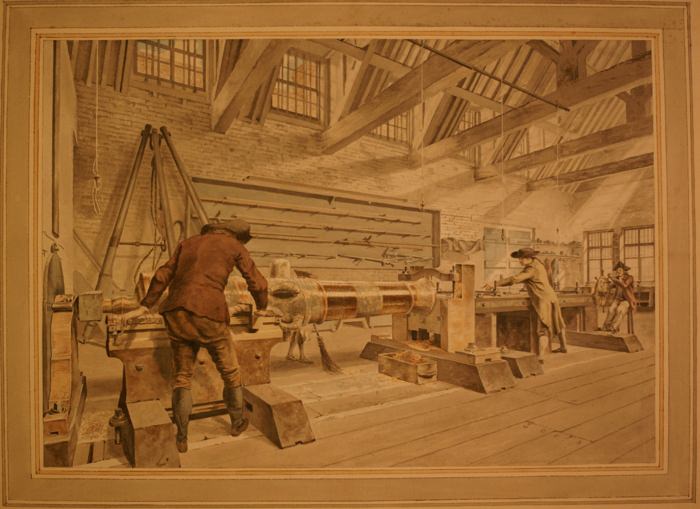

Bearings and rollers come in all shapes and sizes [see example bearings] but were not always made of steel. At one time, they were also made of rock and wood. Their use in early modern history has been found throughout various parts of the world.

- Ball bearings were found on the Roman Nemi ships around 40 C.E.

- Bas reliefs discovered in the around 1850 are said to represent the first recorded use of rollers for transporting building blocks and stone carvings

- The is evidence from pictures of Assyrians moving a human-headed bull approximately 2680 years ago

- Rolling wheeled vehicles are recorded in Uruk pictographs dating back almost 5000 years

- An ancient Chinese pictograph from approximately 3480 years ago shows the spoked wheel was developed in the East by that time

- About 50 wheels or wheeled vehicles have been found in Europe and Western Asia dating to approximately 2000 AD to 3000 AD

- The battering rams of 330 BC were mounted on linear roller bearings containing wooden rollers turned on a lathe

- The Celts developed roller bearings almost 2000 years ago

- The oak hubs on four-wheeled carts were found in Western Jutland in Denmark in 1881 which contained bronze collars and bearings

Now, bearings and rollers are manufactured across the world, in virtually every state, province and city. They’re one of the most needed components in the development in 90% of manufactured electrical or mechanical machinery and human civilization is indebted to its use.

Bearings and rollers have significantly helped optimize manufacturing of all types and has propelled the East and the West into modern civilization.

The mechanics behind the ball and roller bearing

According to the Encyclopedia Britannica, the function of ball bearings is to;

“connect two machine members that move relative to one another in such a manner that the frictional resistance to motion is minimal. In many applications one of the members is a rotating shaft and the other a fixed housing” [Source: Encyclopedia Britannica]

In short, bearings reduce rotational friction of moving parts and support radial and axial loads by replacing sliding friction with rotational friction was is substantially less than sliding friction.

Roller bearings are primarily utilized for heavy-load applications while the ball bearing is primarily used for light-load applications. Bearing only work if each ball is kept evenly separated and spaced throughout the outer races.

The above has to do with bearings that require adequate lubrication, but new type of bearing called ADB (Autonomous Decentralized Bearing) can be used without a cage and doesn’t require lubrication. The ADB bearing was developed by Coo Space Co., and is a product that spaces the balls out without needing a cage to contain them.

See video below for an example of how ADB bearings work:

Bearing cages cause friction so without the cages and evenly distributed balls, you have a unit who’s regular performance is not negatively affected and that doesn’t require lubrication and can last longer than standard traditional bearings.

Bearings and rollers have changed the world, and without them, civilization would not have had the chance to become as technologically advanced as we are today. Bearings (Seismic Isolation Bearings) are so versatile, that they’re even being used to mitigate the destruction caused by earthquakes.